5 Essential Tips for Choosing the Best Cam Switch for Your Needs

In the realm of electrical equipment, choosing the right Cam Switch is crucial for ensuring efficient power management and system reliability. According to a recent industry report by MarketsandMarkets, the global switch market is projected to reach $80.29 billion by 2025, driven by the increasing demand for advanced electrical solutions across various sectors.

However, with the plethora of options available, users often face challenges in selecting the most suitable Cam Switch for their specific applications. Issues such as compatibility with existing systems, load capacity, and environmental resistance can complicate the decision-making process. Understanding these factors is essential for optimizing operational performance and avoiding costly errors.

This blog will explore five essential tips to guide you in choosing the best Cam Switch for your needs, ensuring that you make an informed and strategic investment in your electrical systems.

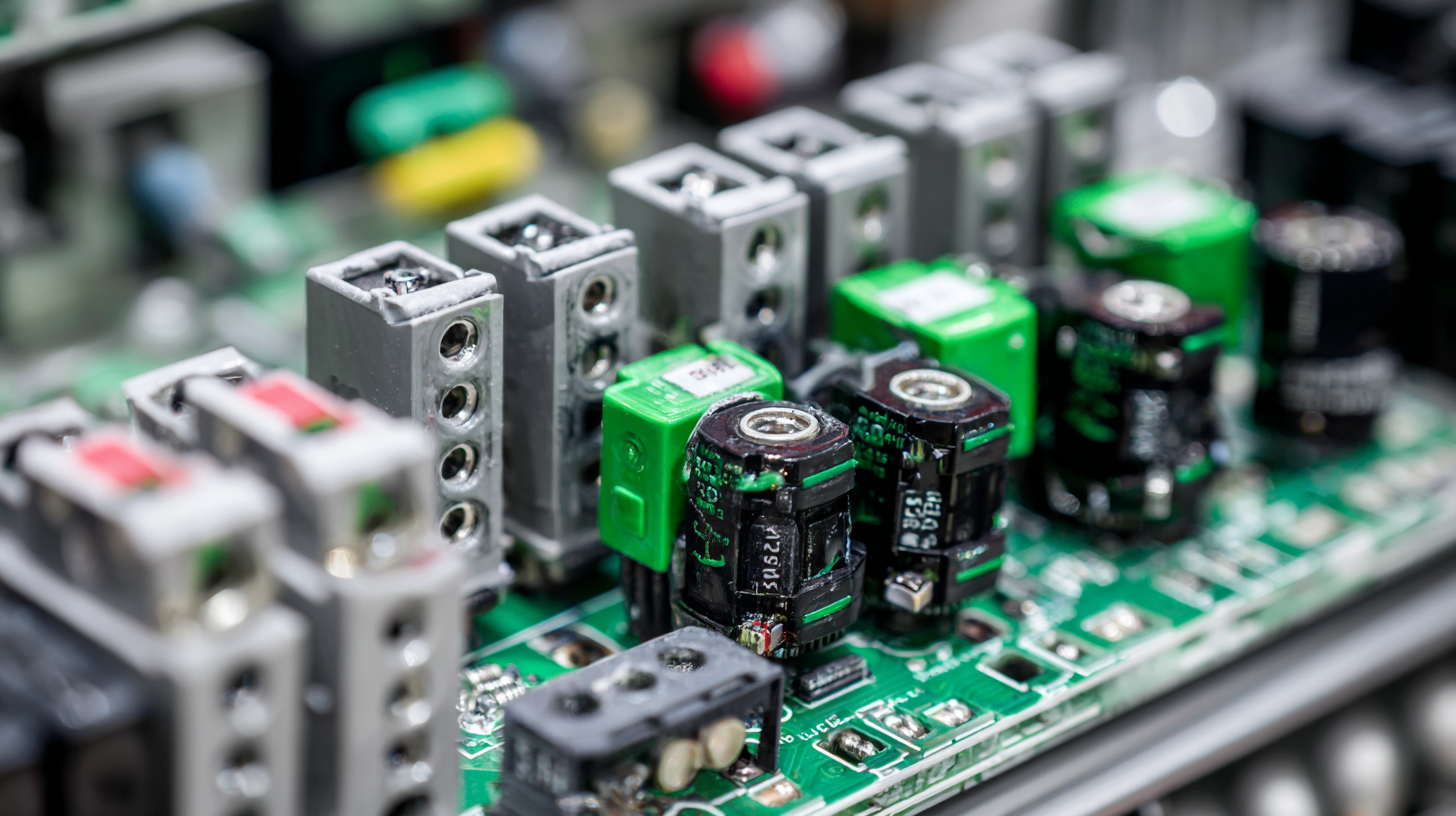

Understanding Cam Switch Types: A Comprehensive Overview

When choosing the right cam switch, understanding the types available is crucial. Cam switches are versatile devices used in numerous applications, from industrial machinery to household appliances. According to a report by Grand View Research, the global cam switch market is projected to grow substantially, with a CAGR of over 5% from 2021 to 2028. This growth is driven by the increasing demand for efficient electrical management systems across various industries.

Tip 1: Always match the cam switch type with your specific application requirements. There are various types of cam switches, including rotary cam switches, toggle cam switches, and key-operated cam switches. Each type has its unique features that cater to different operational needs. Rotary cam switches, for instance, are ideal for applications requiring frequent on-off cycling, while key-operated switches enhance security in sensitive operations.

Tip 2: Consider the switching capacity. According to data from the National Electrical Manufacturers Association, ensuring the cam switch can handle the voltage and current needs of your application is vital to prevent failures. Overloading a cam switch can lead to significant operational downtime and safety hazards, so choosing a switch with higher-rated capacities can provide additional reliability and longevity in performance.

By focusing on the right type of cam switch and understanding its specifications, you can make an informed decision that aligns with your operational needs.

Key Factors in Selecting the Right Cam Switch for Your Application

When selecting the right cam switch for your application, understanding the key factors that influence performance is crucial. One primary consideration is the type of environment in which the switch will operate. For instance, position and safety switches function effectively in various applications, ensuring the precise detection of motion sequences in machinery and plants. According to recent industry reports, switches designed for industrial environments can significantly enhance operational efficiency and safety, with users experiencing up to a 30% improvement in equipment reliability when utilizing advanced switch technologies.

Another essential factor is the compatibility of the cam switch with existing systems. With the advancement in smart technology, cam switches must integrate seamlessly with digital control systems to provide real-time feedback and control. The evolving landscape of smart factory solutions indicates that companies investing in modern switch technologies are likely to see reduced downtime and operational costs, estimated at a reduction of up to 25%. Selecting a cam switch that meets these criteria will ensure that it fulfills the specific needs of your operation while maximizing efficiency and safety.

Evaluating Voltage and Current Ratings for Optimal Performance

When selecting the best cam switch, it is vital to assess voltage and current ratings to ensure optimal performance in your specific application. According to the International Electrotechnical Commission (IEC), cam switches typically operate within a voltage range of 230V to 400V AC. Utilizing a switch that matches or exceeds your system's voltage requirements is crucial for preventing damage and ensuring safety. Additionally, the current rating influences the switch's ability to handle load; for instance, a switch rated at 16A might be suitable for lighter applications, while a higher rating of 63A or more would be necessary for industrial circuits.

Furthermore, consider the environmental conditions in which the cam switch will be operating. When exposed to high humidity or extreme temperatures, choose switches with higher insulation ratings and those designed to withstand such conditions without compromising performance. According to a report by the International Energy Agency (IEA), improper voltage and current handling can lead to efficiency losses of up to 30%, making it essential to select appropriately rated equipment. Remember, optimal performance not only improves functionality but also extends the lifespan of your electrical equipment.

Assessing Durability: Material and Environmental Considerations

When selecting a cam switch, assessing its durability is crucial to ensuring long-term performance. The material used in the construction of the switch significantly impacts its resilience to wear and tear. For indoor applications, standard materials like plastic may suffice, but for outdoor or harsher environments, look for cam switches made of robust materials such as stainless steel or reinforced polycarbonate. These materials can better withstand exposure to moisture, UV rays, and extreme temperatures.

Additionally, consider the environmental factors that may affect the cam switch's lifespan. For instance, if the switch will be used in a high-vibration or dusty environment, opt for switches that feature sealed designs to keep contaminants out. Also, evaluate the IP rating, which indicates the level of protection against dust and water ingress. A higher IP rating means enhanced durability in challenging conditions.

When making your choice, remember to examine the manufacturer's specifications to ensure the switch can endure the environmental conditions it will face. Selecting the right cam switch based on material and environmental considerations will lead to a more reliable and longer-lasting solution for your needs.

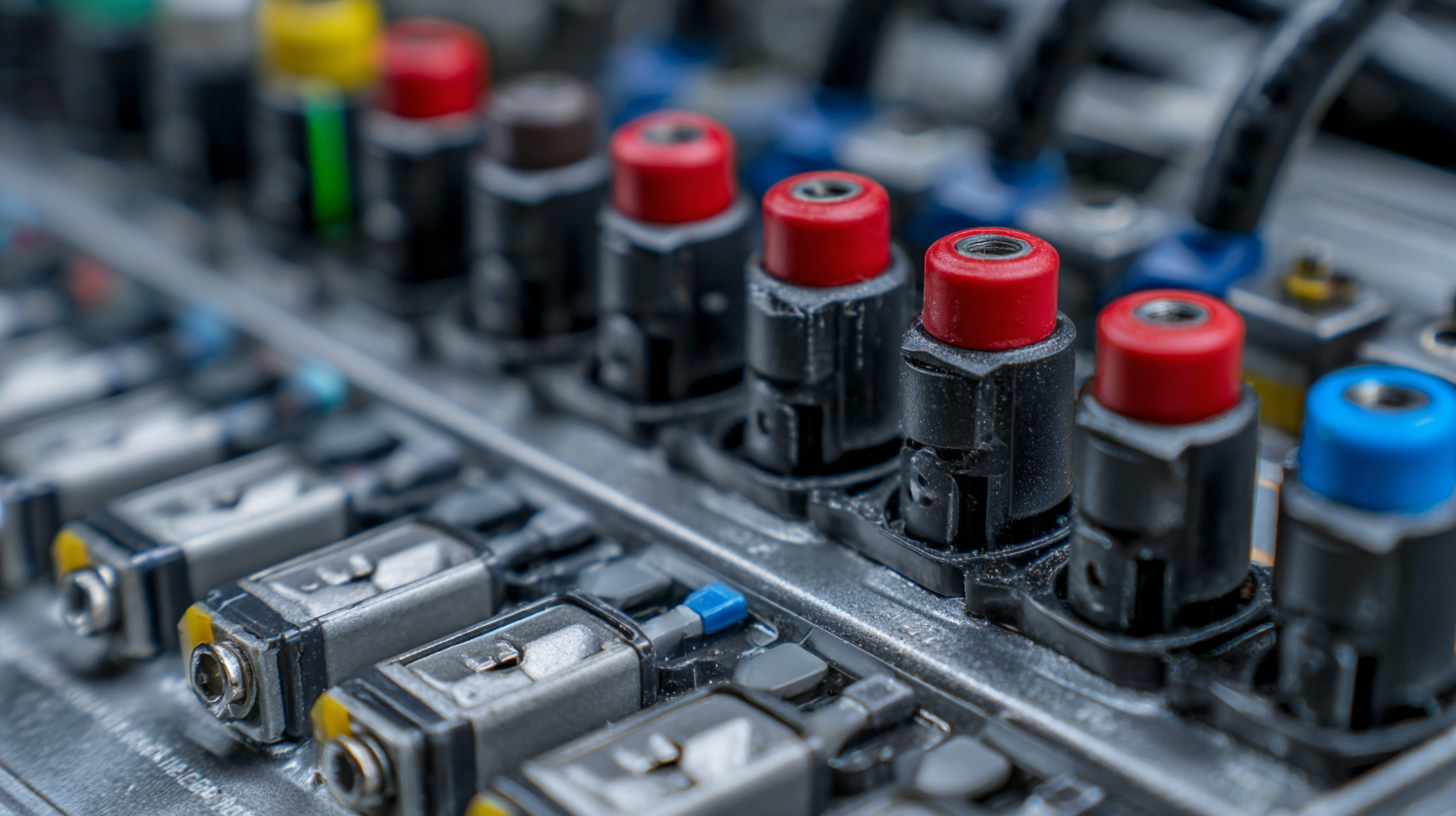

Industry Standards and Certifications to Look for in Cam Switches

When selecting the best cam switch for your applications, it's crucial to consider industry standards and certifications to ensure safety and reliability. Look for switches that comply with the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) standards. These certifications indicate that the switch has undergone rigorous testing and meets specific parameters for performance and durability. With equipment operating in various environments, opting for switches that are rated for different ambient temperatures and environmental conditions is imperative to guarantee optimal functionality.

In addition to IEC and UL certifications, pay attention to the specific ratings like IP (Ingress Protection) ratings, which provide insight into the switch's resistance to dust and moisture. A higher IP rating means better protection against external elements, making it suitable for harsh industrial environments. Furthermore, switches with robust electrical ratings and emergency stop features enhance safety and prevent potential hazards in operational settings. By prioritizing these certifications, you can ensure that your cam switch meets both industry regulations and your specific operational needs.

5 Essential Tips for Choosing the Best Cam Switch for Your Needs

| Feature | Importance | Standards/Certifications | Typical Applications |

|---|---|---|---|

| Durability | High | IP65, NEMA | Industrial machinery |

| Electrical Ratings | High | UL, IEC | Control panels |

| Ease of Installation | Medium | ISO 9001 | Electronics |

| Temperature Rating | High | RoHS, CE | HVAC systems |

| Versatility | Medium | CSA | Various electrical systems |